12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

NAMBOUR EXPO 2024

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

12th APRIL – 14th APRIL 2024

Nambour Showgrounds

Key Event Information

OPENING HOURS

2025 Dates Coming Soon

EXPO TICKETS

Adults Single Day $20 $16

Adult Three Day $25 $20

Seniors Card Single Day $15 $12

Seniors Card Three Day $20 $16

+ Booking Service Fee

Children 16 & Under FREE

LOCATION

Nambour Showgrounds

Coronation Avenue, Nambour

Queensland 4560

ANIMALS

Only licenced assistance animals

permitted at the event.

Event Information

OPENING HOURS

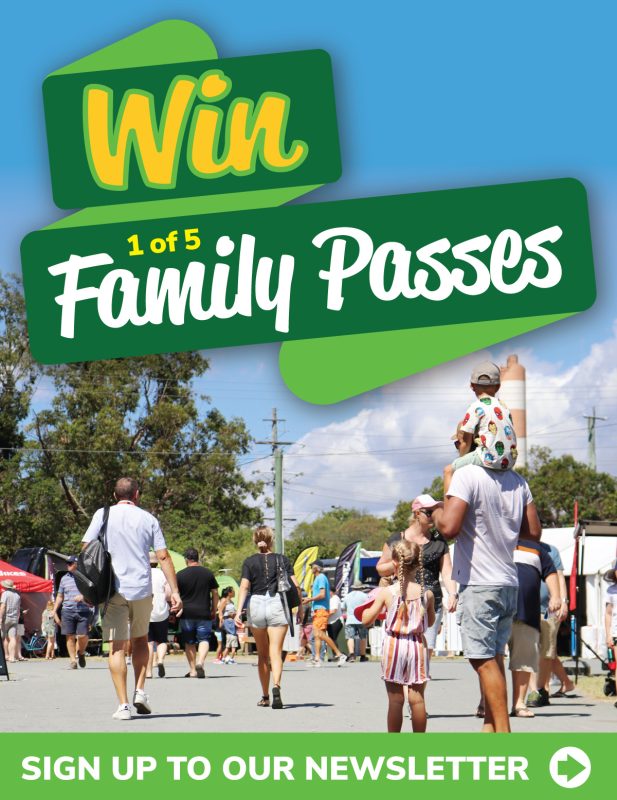

31 March – 2 april

Friday 8:30am – 4:00pm

Saturday 8:30am – 5:00pm

Sunday 8:30am – 4:00pm

EXPO TICKETS

Adults Single Day $15 – Adult Three Day $18

Seniors Card Single Day $12 – Seniors Card Three Day $15

Children 16 & Under FREE

+ Booking Service Fee

LOCATION

Nambour Showgrounds

Coronation Avenue

Nambour

QLD, 4560

Tickets are available at the gate by credit card and eftpos ONLY. No cash sales.

*Limited tents on display. No Dogs or Pets allowed.

Step into Adventure at the Nambour Expo

Tickets are available at the gate by credit card and eftpos ONLY. No cash sales.

*Limited tents on display. No Dogs or Pets allowed.

Nambour expo… The Regions Largest and Most Successful Event of its Kind

Your adventure begins at the Nambour Expo, one of the largest outdoor adventure events in the region. Browse and compare the latest caravans, camper trailers, motorhomes, accessories, fishing gear and more. Plus discover new holiday and touring destinations, all in one convenient location. There’s plenty to see across the weekend, including great entertainment for the whole family and fantastic prizes to be won!

We look forward to seeing you at the Nambour Expo!

Step into Adventure at the Nambour Expo. Your next adventure awaits, thanks to the ultimate outdoor event of the year. That’s right, the Nambour Expo is back for 2024 and it’s bigger and better than ever before. The premier one-stop-shop features auto and 4WD accessories, caravans, camper trailers, marine and much more.

Bring your next adventure plan to life, discover new holiday destinations, and watch experts demonstrate first-rate outdoor gear. There’s also great family entertainment with Wildlife Unleashed Show for the whole family, Camp Cooking with Kingbrown and RACQ On-Road & Off-Road Safety presentations. Don’t miss the fantastic prizes to be won just by attending and scanning your ticket. With so much to see and do, you’ll be spoiled for choice at the 2024 Nambour Expo.

The Camp Oven King: Kingbrown

Ron Wilson aka ‘Kingbrown’ The Camp Oven King is one of Australia’s leading authorities on campfire cooking. He is in fact internationally known for his skills using traditional Australian camp ovens. These skills were honed with a camp oven catering business where he cooked for many thousands

READ MORERACQ On & Off-Road Safety Presentations

Join the team for an informative and engaging series of talks, designed to equip you with essential knowledge for a safe and enjoyable journey. With three talks held daily, RACQ will cover a range of topics to ensure you’re prepared and confident on the road.

READ MOREWildlife Unleashed

Wildlife Unleashed is not just a company; it is a heartfelt mission to educate and inspire people about the wonders of the natural world. Founded by Adele and Mick Bender, they have a lifelong dedication to wildlife and conservation. Mick wrangles some of the world’s most venomous

READ MORENambour expo… The Regions Largest and Most Successful Event of its Kind

Your adventure begins at the Nambour Expo, one of the largest outdoor adventure events in the region. Browse and compare the latest caravans, camper trailers, motorhomes, accessories, fishing gear and more. Plus discover new holiday and touring destinations, all in one convenient location. There’s plenty to see across the weekend, including great entertainment for the whole family and fantastic prizes to be won!

We look forward to seeing you at the Nambour Expo!

Event Information

OPENING HOURS

12 APRIL – 14 april 2024

Friday 8:30am – 4:00pm

Saturday 8:30am – 5:00pm

Sunday 8:30am – 4:00pm

LOCATION

Nambour Showgrounds

Coronation Avenue

Nambour

QLD, 4560

Tickets are available at the gate by credit card and eftpos ONLY. No cash sales.

*Limited tents on display. No Dogs or Pets allowed.

Engines Roaring – Campers in Tow – Step into Adventure!

Gear up and get ready – your next scenic feat is at your fingertips thanks to the ultimate outdoor event of the year. That’s right, the Nambour Expo is back for 2024 and it’s bigger and better than ever before! The premier one-stop-shop features 4x4s, caravans, camper trailers, motorhomes, boating, fishing gear accessories and more.

Bring your next adventure plan to life, discover new holiday destinations, and watch experts demonstrate first-rate outdoor gear. There’s also great entertainment for the whole family and fantastic prizes to be won. With so much to see and do, you’ll be spoiled for choice!

STEP INTO ADVENTURE AT THE NAMBOUR EXPO

Nambour expo… The Regions Largest and Most Successful Event of its Kind

Your adventure begins at the Nambour Expo, one of the largest outdoor adventure events in the region. Browse and compare the latest caravans, camper trailers, motorhomes, accessories, fishing gear and more. Plus discover new holiday and touring destinations, all in one convenient location. There’s plenty to see across the weekend, including great entertainment for the whole family and fantastic prizes to be won!

We look forward to seeing you at the Nambour Expo!